We continue the review of interviews dedicated to MCS collaborators. It’s the turn of Giovanni Frison, historical memory of the company and manager of the membrane switches design.

Today we get to know an MCS “veteran” a little better: Giovanni Frison, who has been with the company since 1983. Giovanni is so professional who is respected and appreciated by colleagues and customers. He has soft skills in graphics, electronics and mechanics. Nowadays he mainly deals with the design of membrane switches, but also with mechanical and graphic customization projects for commercial electronic enclosures.

Hi Giovanni, what can you tell us about your early years of work? What do you currently do in MCS?

In the early years of work the resources available were different, we didn’t have the equipment and materials that we have today. There has obviously been an evolution, an implementation of technologies and processes to offer various types of products, to improve the services offered.

An important thing, in my opinion, is that development has involved and still involves all aspects of the company, from equipment to staff, from production processes to marketing.

Personally, I’ve always dealt with the technical aspects. I worked in all design sectors and for a certain period of time also in the production department, to understand the whole manufacturing process. Today I mainly follow the design of membrane switches.

In this regard, according to your experience, what are the critical aspects in the design of a membrane switch?

To obtain a reliable keyboard over time, it must have a good degree of IP protection (according to the standard CEI EN 60259/1997 ), especially for the circuit part of the membrane switch which is enclosed with protective films.

It is known that membrane switches are sensitive to humidity and environmental factors, therefore it is necessary to consider the use of the membrane switch, the environmental context in which it will operate.

Depending on the case, it may be necessary to use particular qualities of polyester.

Recently, a case history was published on the site’s blog which deepen the design of a membrane switches for artificial snow systems, therefore subject to strong solar radiation.

In this case we have used polyester with a UV filter which does not deteriorate and retains its characteristics even if it is exposed to the sun.

What methods do you use to create new ideas or imagine new solutions?

First of all, we consult with our suppliers to understand if there are any materials or production processes that can be improved. We attended the exhibitions to find out about our sector news. We do research on the web and we discuss it with colleagues.

Summarizing, we can identify three fundamental factors: experience, updating and teamwork. If there are special requests from a customer, we hold targeted meetings in which to compare and put together the various ideas, in order to find best solution.

In your design activity, what comes first – paper or PC?

At the beginning of the design process there is always a short briefing with the commercial side for the transfer of the first information agreed with the customer. A proposal is then elaborated, at the end a summary document is sent for customer approval.

When faced with requests from clients who don’t have clear ideas, we prefer to develop a draft on paper because it is easier to make any corrections or changes. Once the draft has been approved, we move on to design software, the production specifications and the plants are created and production starts.

What do you think are the strong points of MCS?

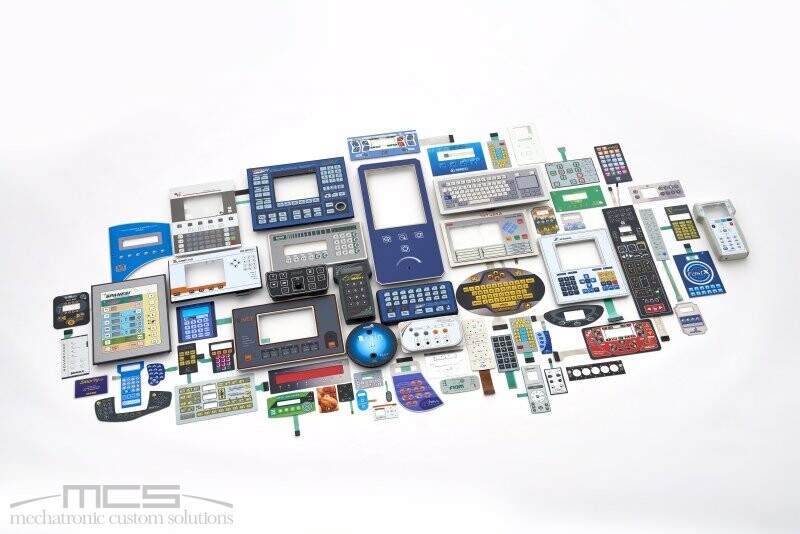

Customers appreciate the breadth of solutions that we are able to offer.

In fact, we carry out various types of processing, printing and even assembly.

With MCS, a potential customer can see manufactured a large part of his product without resorting to multiple suppliers.

We also ensure rapid responses, both in proposing our solutions to the customer and in delivering the manufactured product.

What are the aspects you like most about your job? A project you are particularly proud of?

I would say the variety. It is a job that requires always finding different solutions because the customers’ requests are very varied. I like to face and solve new problems. If the customer then sees that you have managed to solve one of his problems and expresses his appreciation, then satisfaction is maximum.

I’ve been involved in so many projects that I’m proud of, but there are so many that I just can’t pinpoint one in particular.

Interview by Mauro Zamberlan – MCS Marketing Office