FAQ

Looking for a reliable supplier who can offer you a wide range of products and services in a coordinated and effective way?

How often are you forced to make realize to various suppliers about several parts of the same product, taking charge of the management and synchronization of the different suppliers who often do not respond on the same time and involve delays compared to your schedule?

- Design and production of customized electronic enclosures in plastic or metal materials. With finishing treatments and possible completion with membrane switches, labels, silkscreen and digital printing, slides and milled mechanical details. Made with in-house processes of cnc machining from full on plastic or aluminum, 3D printing in PA12 material, in plastic and metal bending and thermoforming.

- Design and production of customized display frames made of plastic or metal. Made by cnc milling processes from sheet or 3D printing processes in PA12 material. Finished with aesthetic painting, screen printing, labeling, digital printing. Addition of O-rings or die-cut gaskets, studs and threaded inserts. Shapes, sizes, and finishes are studied out with the client for a highly customized result.

News

Customized enclosures for AGV: A successful case study

This post examines a project for a leading company in Emilia-Romagna that produces AGV (Automated Guided Vehicles). The company required a custom solution for the handheld controller used on their vehicles. The project involved designing and producing a tailored enclosure that met specific ergonomic, functional, and safety requirements, ultimately enhancing the usability and distinctiveness of the product.

Choosing the right double-sided adhesive: a factor not to be underestimated.

Gluing is an important aspect in the world of membrane switch, as well as in electronic enclosures and display frames. Selecting the right double-sided adhesives is crucial to ensure the durability and effectiveness of our products.

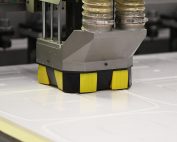

Innovation and precision in mechanical sheet processing.

We constantly invest in the customization of solutions for electronics, a fact well-recognized by our customers. One of our core strengths lies in mechanical sheet processing, which we consider a pivotal milestone in our production process. Since our initial acquisition in 2005, this aspect has undergone remarkable advancements, reflecting our ongoing commitment to innovation and improvement.

Empowering Female Voices within the Company

On the occasion of International Women’s Day, 8 March, we present an interview to two of our employees in the purchasing office: Head Sonia and colleague Amanjot who also performs receptionist functions. A brief dialogue with two voices to highlight the experiences and opinions of women in the world of work.