Interview with Mr. Alessandro Vignaga, CEO and Sales Manager of MCS, who discusses the investments the company has put in place to improve its offerings and consolidate its competitiveness in view of the challenges of future markets.

A number of new things have been reported recently on LinkedIn: a new 3D printing plant, the new liquid coating cabin: when the game gets tough, the tough start investing in innovation, or am I wrong?

In my opinion, innovation and investment in new equipment are the lifeblood for us as well as for any company. All investments are motivated and incentivized by several factors such as: curiosity and passion for news sector, production needs, implementation of complementary processes, and-last but not least-the desire to provide more and more value to our customers.

The company has always believed in 3D printing technology. There is an in-depth discussion on the company blog page about the fact that you have enhanced this service. Have you tested the new system yet?

The new plant is operational and is giving us and to our customers continuous satisfaction. As we have highlighted in the recent published post, it is a technology that we already knew and had, we have simply expanded it for production needs and quality yield.

What can you tell us about the renewed liquid coating plant?

In this case it all started from a need related to interior cabin space. Increasingly, our products are medium to large in size, or small in size but in large quantities. It is important, therefore, to be able to have a comfortable cabin large enough to place the material to be coated and varnished inside.

Can you anticipate any other news coming? Will there be further investment in R&D?

The current assembly area is starting to be a bit too small, so we are building a new assembly department with larger area and passageways, obtained from an extension of an existing loft.

The new department will have individual workstations for each operator, with ergonomic work tables where it will be possible to work seated, with a stool, or even standing thanks to height-adjustable tops.

Another investment is related to the implementation of a new sandblasting machine/shot penning machine, to improve and even more effectively manage the post-processing activities of parts made in 3D.

The new machinery will arrive in December: this unfortunately requires a change in the company’s internal layout, with movements of machinery and departments, but that’s part of the game.

Finally, we are considering a new large-format milling machine, but we are still in the testing and negotiation phase.

How do you see the current market situation?

The company is growing and we are constantly encouraged by positive responses from customers. Our products are used in a variety of fields: automotive, agricultural, industrial, medical, marine, automation, etc.

These are sectors with products based on high technological content and in which, in my opinion, Italy is very strong. However, we are in a period where there is little stability (prices and availability) in the market for raw materials and components, and this complicates the management of each single order.

How does rising energy costs affect it?

Rising energy costs are there for all to see. Fortunately (or unfortunately if we look at it from the side of climate change) we come from seasons with almost always beautiful and sunny days, this has allowed for the best work and production our photovoltaic system of 100kw.

Using mostly self-generated energy, the increase in bills was significant but small compared to others. Clearly, we are now heading toward a dark season with bad weather, in which our plant will produce very little. It will also take over more natural gas for the company’s internal heating. We’ll see, but we have no other alternatives.

Is the company turning 40 years old in 2023? How will you celebrate this important milestone?

Of course, it is an important milestone. We often find ourselves talking about it in the family, retracing the various stages and evolution of the company.

In 1983 MCS had a different meaning i.e. Master for Printed Circuits and everything was done in a very small office.

Then in the mid-1990s the beginning of production activity with silkscreen printing processes, up to the present day. Honestly, I have not yet decided how we will celebrate this anniversary.

A message/advice for your clients?

Contact us, put us to the test, but most importantly, visit us. It is always very difficult to convey to customers what we are like and what we do.

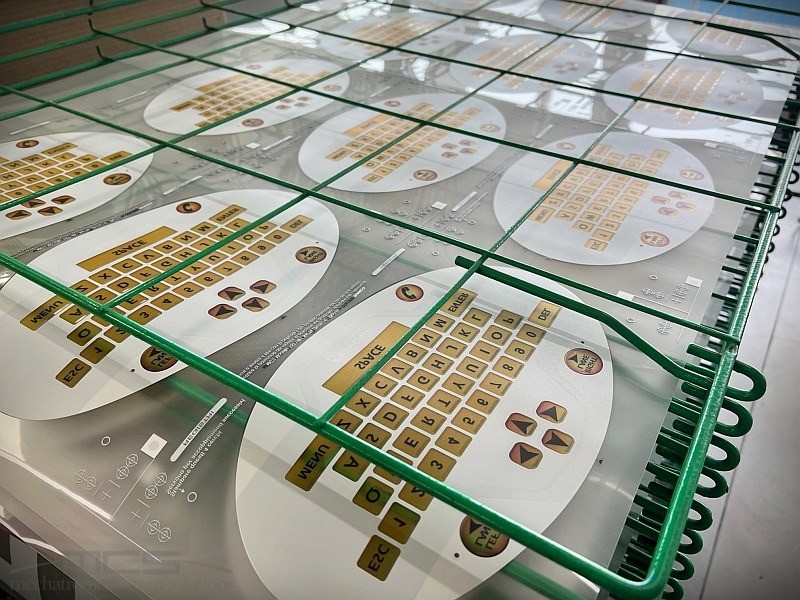

The look of a customized enclosure, a display frame or a membrane switch represents the communication interface with the user (HMI Human Machine Interface).

First and foremost, meeting on site allows people to see and touch different products: the website is a constantly updated showcase, but we have much more in our showroom.

Very often, customers come in to explore more about a product or service, and then seeing the whole, parallel needs arise that we are able to satisfy.

It is also nice to show that we are not a contractor: what we offer we make with our own processes, from design to production. The use of external subcontractors is very limited and sporadic, linked to some sideline activities.

Text by MCS Marketing Office